Customized meshes in Austria

Table of content

The product

BSTG is the company in the Pittini Group devoted to the production of customized electrowelded meshes austria intended to be used in reinforced concrete works for specific projects or prefabricated works. Custom wire mesh is designed by our engineering department according to customers’ static specifications and size requirements. Wire mesh characteristics such as wire diameter, length and width can be freely selected and combined.

This type of meshes breaks down as follows:

- Unidirectional electro-welded meshes: longitudinal bars play a role in terms of statics, whereas transversal bars are only used as fitting bars.

- Bidirectional electro-welded meshes:

- both longitudinal and transversal bars play a role in terms of statics.

- Electro-welded meshes for reinforced concrete: in some areas, there is an increased number of longitudinal bars.

Customised electro-welded meshes are available upon request (terms of delivery: about 10/14 days). They are directly delivered by the manufacturing plant to the site of the project or prefabricated work. Our teams can help you to design customised electro-welded meshes or reinforcements.

Unidirectional electro-welded meshes

Bidirectional electro-welded meshes

The customized meshes produced in Osoppo obtained the EPD Certification – Environmental Product Declaration – by the certifying partner ICMQ, the Institute for certification and quality branding for products and services for construction.

Advantages

Main advantages of customised electro-welded meshes:

- Fit the building element perfectly; length and width are customised

- The mesh is long up to 14.0 m and wide 1.0 m to 3.35 m (weld width 3.30 m)

- No additional costs for on-site cuts

- No wastes

- Fit the required steel cross-section perfectly thanks to the possibility of using of bars with different diameters (4.0 to 16.0 mm, double bars up to 12.0 mm)

- No useless materials for overlaps

- No static height losses (one-level overlaps); overlaps are eliminated as much as possible

- Reduced laying time thanks to the use of one single mesh for longitudinal and transversal reinforcement.

To complete the product range, BSTG also manufactures a wide range of standard electro-welded wire meshes for the Austrian market in its two production facilities located in Austria.

Laying of Customised Meshes

Meshes can be turned upside down to change the direction of bars (transversal bars below and longitudinal bars above). BE CAREFUL when deciding the positions for overlaps.

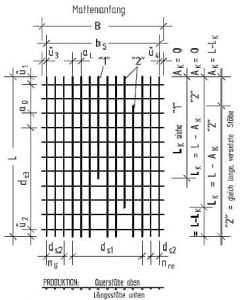

|

Characteristics |

|

L |

Mesh length up to 12.0 m |

B |

Mesh width up to 3.10 m |

b S |

Weld width up to 3.00 m |

a L |

Distance between longitudinal bars starting from 50 mm openings or without openings |

a Q |

Distance between transversal bars ≥ 25mm |

d s1 |

Longitudinal bar Ø in the inner area, many options to choose from according to weldability |

d s2 |

Longitudinal bar Ø in the peripheral area ds1 ±2mm and weldability |

n li/re |

Number of peripheral longitudinal bars on the left/right edge |

d s3 |

Transversal bar Ø, many options to choose from according to weldability |

ü 1 |

Leading tail ≤ Ø x 100 mm |

ü 2 |

Trailing tail ≤ Ø x 100 mm |

ü 3 |

Left tail ≥ 10 to 800 mm (starting from diam. 8,0 mm) |

ü 4 |

Right tail ≥ 10 to 800 mm (starting from diam. 8,0 mm) |

A k |

Distance between short bars from the beginning of the mesh |

L K |

Short bar length |

Sales Organization

A continuous and reliable service is guaranteed by Pittini Group’s Sales Department.

Contact our designated representative: