INNOV-ARC

Table of content

High performance welding wires

PITTARC has anticipated the most stringent market requirements and has recently started a new line for the production of wires to be used in the most challenging applications. This new product line is called INNOV-ARC welding wires.

So far, all quality improvements in solid GMAW welding wires have only led to changes in their manufacturing process. However, these changes are limited by the need to balance high productivity and low impact on manufacturing costs. In order to overcome these limits, PITTARC has decided to keep the manufacturing process unchanged, this process being now fully optimised and stabilised, and to apply a further surface treatment after the skin-pass step (which is the last step of copper coating and calibration). This treatment made by special equipment consists in deep cleaning and further polishing of copper wires, which make them especially smooth. This treatment not only ensures optimal feeding.

Advantages of Innov-arc welding wires:

- Consistent welding performance

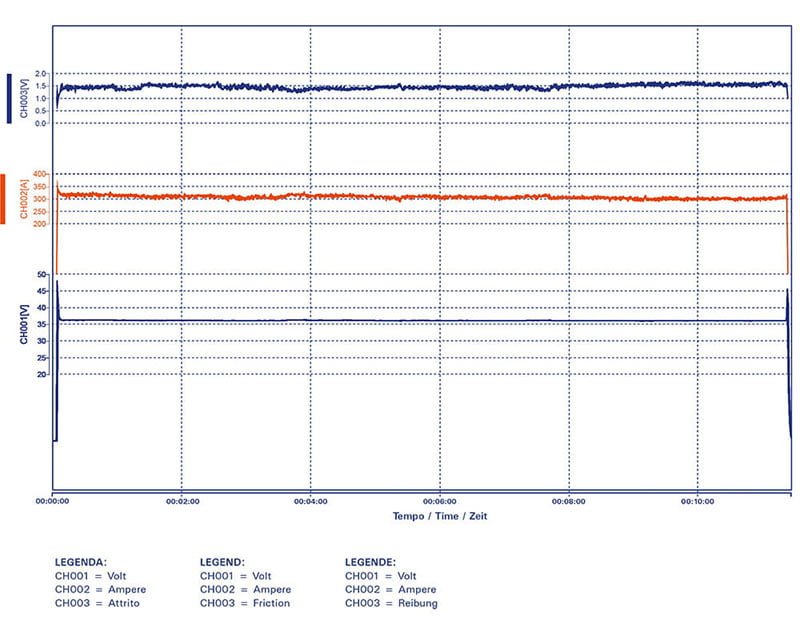

- Perfect arc stability with low feeding force

- Excellent feeding also with very long feed distances and high wire feed speeds

- Extremely low overall spatters

- Optimal welding seam appearance

- Low nozzle wear

- Reduced equipment downtime for liner cleaning

Verified high welding performance

INNOV-ARC wires were submitted to operational tests at the laboratories of the Italian Welding Institute, whose instructors were very favourably impressed by their results.

This surface treatment can be applied to any type of wire, regardless of its chemical composition, diameter and packaging.